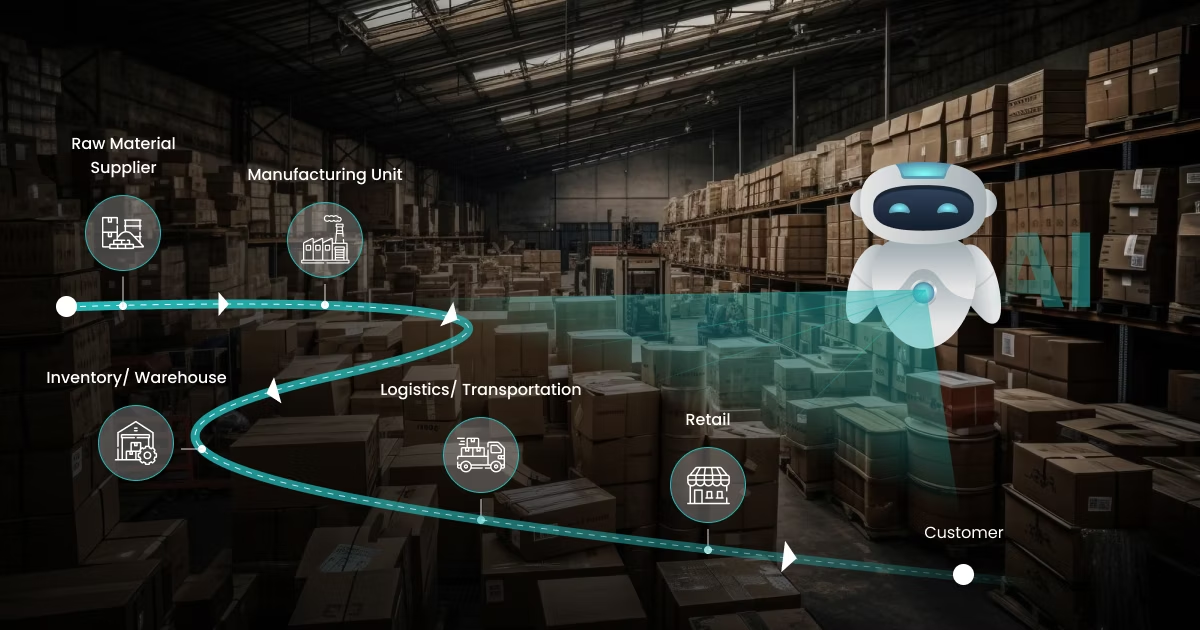

In today’s fast-paced industrial landscape, manufacturing and supply chain sectors face growing challenges — from unpredictable demand and rising costs to global disruptions. AI solutions for manufacturing and supply chain optimization are reshaping how companies operate, automate, and compete. With intelligent automation, predictive maintenance, and smart logistics, AI is enabling businesses to streamline operations, minimize risks, and boost productivity.

🏭 Manufacturing & Logistics AI Use Cases

Predictive Maintenance

Monitor equipment with AI-driven sensing and analytics to schedule maintenance before breakdowns.Automated Quality Inspection

Use computer vision to detect product flaws in real time, ensuring consistency and reducing waste.Digital Twin Simulations

Model production lines digitally to simulate changes and enhance efficiencies before implementing in the real world.

🚚 Supply Chain & Inventory Optimization

Demand Forecasting & Inventory Planning

Leverage AI to forecast demand, align inventory, and reduce overstock or shortages.Smart Warehouse Automation

Deploy AI-enabled robots and software to streamline picking, packing, and storage within your facility.Logistics Route Optimization

Use real-time traffic, weather, and delivery patterns to create shortest and most efficient routes.

How Aigentora Helps You Automate

Modeled after the “How It Works” section on your site, this guides readers through your process clearly:

Discovery & Industry Benchmarking

Assess your current systems and map out AI opportunities.Solution Design & Technology Selection

Choose the right AI tools — from computer vision to data modeling — tailored to your operations.Integration & Custom Development

Securely connect AI systems to your ERP, CMMS, or logistics platforms.Pilot Launch & Iteration

Run a small-scale, measurable deployment; collect feedback; then refine for rollout.Scalable Deployment & Monitoring

Expand high-performing solutions across operations with real-time monitoring and ROI tracking.

💡 Key Benefits of AI-Powered Manufacturing

Predictive Maintenance: Minimize downtime and reduce costs by detecting issues early.

Quality Assurance: Real-time defect detection with computer vision.

Inventory Optimization: Avoid overstocking and understocking with intelligent demand prediction.

Process Automation: Automate repetitive tasks for improved efficiency.

Logistics Optimization: Reduce transit time and costs with smart route planning.

Data-Driven Decisions: Leverage insights for strategic planning and faster decision-making.

🚀 Why Businesses Need AI Now

With increasing complexity and global competition, manufacturers and logistics companies must adapt quickly. AI provides a competitive edge by making processes leaner, smarter, and more responsive.

✅ Key Advantages of AI in Manufacturing & Supply Chain

1. Predictive Maintenance:AI analyzes sensor data to predict machine failures before they happen—minimizing downtime and saving on repair costs.

2. Real-Time Inventory Management:AI-driven systems ensure accurate stock levels, reducing overstocking or stockouts while improving fulfillment rates.

3. Demand Forecasting:Machine learning models forecast demand trends using historical and real-time data, helping manufacturers optimize production schedules.

4. Production Efficiency:AI algorithms help automate and fine-tune production lines, improving output, reducing waste, and enhancing overall efficiency.

5. Quality Control Automation:Computer vision systems powered by AI can detect product defects more accurately and consistently than manual inspections.

6. Supply Chain Transparency:AI enables better visibility across the supply chain by tracking shipments, identifying bottlenecks, and recommending improvements.

7. Cost Reduction:By streamlining operations, reducing waste, and optimizing logistics, AI significantly cuts operational costs.

Data Security & Compliance

Data Security & Compliance

AI in manufacturing doesn’t just boost efficiency — it also ensures secure handling of sensitive data. Enterprises can enforce strict data governance and stay compliant with industry regulations.

🧠 Frequently Asked Questions About AI in Manufacturing & Supply Chain Optimization

Artificial intelligence is transforming manufacturing and supply chains by enabling data-driven decision-making, automating repetitive tasks, and improving operational efficiency. AI tools help manufacturers predict equipment failures, optimize production schedules, enhance product quality, and reduce downtime. In the supply chain, AI is used to improve demand forecasting, route planning, inventory management, and supplier risk assessment. By automating and optimizing these complex processes, companies reduce costs and gain a competitive edge in today’s fast-paced market.

Predictive maintenance uses AI algorithms to monitor machine performance in real-time and detect early warning signs of mechanical issues. Instead of waiting for equipment to break down, AI predicts potential failures and alerts operators to perform timely maintenance. This proactive approach significantly reduces unplanned downtime, extends equipment life, and lowers repair costs—making the manufacturing process smoother and more efficient.

Yes, AI can dramatically improve inventory accuracy by analyzing historical data, sales trends, and current stock levels to predict future inventory needs. AI algorithms automate stock replenishment, reduce human error, and prevent issues like overstocking or stockouts. This results in lower carrying costs, optimized storage space, and better customer satisfaction by ensuring products are always available when needed.

AI integrates data from multiple sources—such as sensors, GPS, ERP systems, and third-party logistics—to offer real-time visibility across the entire supply chain. It helps companies track shipments, anticipate disruptions, optimize delivery routes, and make agile decisions during unexpected changes. This transparency improves efficiency, reduces transportation costs, and ensures faster, more reliable delivery of goods.

AI-driven demand forecasting uses machine learning models to analyze historical sales data, market trends, seasonality, and even external factors like weather or economic conditions. This enables highly accurate demand predictions that help companies plan production, allocate resources, and reduce excess inventory. Better forecasting reduces waste, enhances cash flow, and improves overall responsiveness to market demands.

While AI adoption may seem expensive at first glance, it’s increasingly accessible for small and mid-sized enterprises (SMEs) thanks to cloud-based tools and AI-as-a-Service platforms. These solutions allow businesses to implement AI without significant upfront investment in infrastructure. Over time, AI pays for itself by improving productivity, reducing labor costs, and minimizing production losses.

AI-based quality inspection systems use computer vision and machine learning to identify defects in products during or after the manufacturing process. These systems can detect inconsistencies with greater speed and accuracy than human inspectors, ensuring higher product quality and fewer returns. They also enable 24/7 monitoring, reduce inspection time, and ensure consistent standards across production lines.

AI is being adopted across a wide range of industries, including automotive, electronics, pharmaceuticals, consumer goods, aerospace, and food and beverage. Each of these sectors benefits from enhanced production planning, quality control, and supply chain agility. AI also supports sustainability initiatives by reducing waste, optimizing energy consumption, and enabling circular manufacturing models.